Working in a sustainability role, I’ve heard it all: “Concrete is bad for the environment,” or “concrete can’t be sustainable.” But here’s the truth: “CONCRETE IS SUSTAINABLE!”

Concrete is the second most consumed material on Earth, after water. It has been in use for nearly 2,000 years, dating back to the Roman Empire, enabling the construction of massive structures like aqueducts and the Pantheon, which was completed around 125 AD and remains standing today. So why is concrete viewed as bad for the environment, especially when it comes to resiliency and durability? Because it is high in embodied carbon.

Embodied carbon from building materials contributes to approximately 11% of the annual global greenhouse gas (GHG) emissions (Source: Global Alliance for Buildings and Construction). Concrete, iron, and steel alone contribute approximately 9% to the annual global GHG emissions. Concrete acts like a multiplier, making it one of the most significant single sources of GHG emissions in the building materials category. This is because the key ingredient in the production of concrete is cement, which contributes 7-8% to the annual GHG emissions worldwide.

So why do we still use it? Because concrete delivers exceptional longevity, resilience, and performance, making it an essential component of a sustainable building structure.

Short-Term Goals vs. Long-Term Thinking

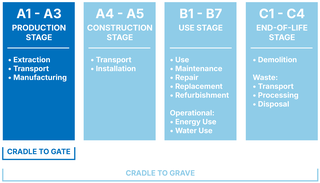

Too often, project decisions are driven by short-term metrics like upfront costs or rapid timelines. When sustainability is deemed a driver, architects and engineers often assess the environmental impact by reviewing each material’s global warming potential (GWP). GWP is reported via an environmental product declaration (EPD), which is a document that reports on the life cycle assessment (LCA) of a product’s global warming potential (GWP). For precast concrete, as with many other construction materials, EPDs reflect the GWP from cradle to gate, meaning they only include the carbon emissions from raw material extraction, transportation, and manufacturing, overlooking the total environmental impact over its entire life cycle, or cradle to grave. It does not take into account transportation to the construction site, reduced construction environmental impacts, the operational performance and the low maintenance advantage of using prefabricated concrete. To understand the environmental impact, it is important to include concrete’s longevity, durability, and efficiency in terms of total environmental impact over its entire life cycle.

Figure 1: Stages of a Life Cycle Assessment (LCA)

Understanding EPDs & Life Cycle Impacts

EPDs are critical tools for making informed design decisions. However, it’s essential to know how to read an EPD. When comparing product EPDs, it’s crucial to understand the scope or life cycle stages included, data sources used, and declared unit, as not all EPDs use the same product category rules (PCRs) that define the LCA. Other factors should also be considered when assessing GWP, such as regionalization, product type, and reinforcement ratio, as the product application has a significant impact on the product's embedded carbon. The Precast/Prestressed Concrete Institute (PCI) has recently updated its industry-wide EPDs and has attempted to regionalize them for fairer comparisons based on geography and product type. However, it is also crucial to recognize that these regional EPDs encompass a wide range of products, which somewhat complicates the interpretation of the data.

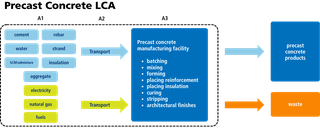

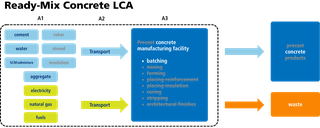

Prefabricated Concrete vs Cast-in-Place

If you’re comparing precast to ready-mix, STOP! Precast is not ready-mix. Precast concrete and ready-mix are distinct types of concrete with different production and application methods and composition. Ready-mix concrete is a component of precast products, and does not include reinforcement, insulation, and all the other materials that go into precast products.

Precast concrete offers a full system solution, providing structural strength, architectural finishes, and even interior benefits like integrated insulation and fire resistance. Its thermal mass, continuous insulation, and lower maintenance improve whole-life performance, making it a more efficient and durable option over time.

There’s a misconception that prefabricated concrete is more resource-intensive than cast-in-place. In reality, it’s often the opposite. Prefabricated concrete can reduce material usage by as much as 30–50% compared to traditional cast-in-place reinforced slabs, thanks to optimized shapes and integrated systems.

Because components are manufactured off-site, there is less waste, forms aren’t stored on-site, fewer deliveries occur, and more controlled curing conditions are maintained. That translates to less on-site disruption, faster schedules, better quality, crews working more efficiently and safely, and everything from curing to finishing is quality-controlled. (Source: International Journal of Innovative Research in Science Engineering and Technology). In addition, prestressed concrete can withstand greater tensile forces, reduce cracking, have a greater load capacity, and exhibit improved durability and longevity compared to conventional reinforced concrete.

Designing for Sustainable Impact

Want to make precast even more sustainable? Start with design.

- Integrate insulation within wall panels to reduce concrete usage and HVAC demand.

- Design roof systems to structurally accommodate solar panels, green roofs, or stormwater capture.

- Leverage the thermal mass of concrete for passive energy benefits.

And at the end of its useful life, precast concrete doesn’t go to waste; it can be reconfigured into another structure, and it’s crushable, reusable, and recyclable (Source: Precast/Prestressed Concrete Institute). That’s circular thinking in action.

What We’re Doing as a Prefabrication Manufacturer

Across the industry, and within our company, we’re advancing sustainability every day:

- Auditing facilities to identify and implement measures that reduce energy and water consumption in both production processes and general operations.

- Transitioning to more efficient and lower-impact fuel sources.

- Researching and applying mix development practices that incorporate supplementary cementitious materials (SCMs) and other sustainable alternatives.

- Recycling manufacturing materials and water for reuse within operations and construction services processes.

- Identifying regional opportunities and sharing best practices across the organization to strengthen Wells’ environmental stewardship.

- Collaborating with suppliers and partners to optimize material procurement and transportation methods.

It’s a continuous, never-ending process—but one we’re committed to.

Bringing it Full Circle

At the end of the day, our goal isn’t just to meet today’s green building standards; it’s to create landmarks that last. Roman concrete structures have lasted for thousands of years. That kind of durability is the original sustainability, and that’s what drives our work every day: designing and delivering high-performance buildings that are efficient, resilient, and enduring. Sustainability doesn’t mean sacrificing performance; it means designing for it from the start.

About the Author

As sustainability manager, Rick leverages over 30 years of experience in the chemical, precast, and materials industries to drive environmental initiatives at Wells. With a background in quality management, process improvement, and mix design optimization, Rick has gained a comprehensive understanding of sustainability through roles in materials management and continuous improvement. Known for his collaborative approach, Rick fosters company-wide awareness of the interdependence of manufacturing practices and sustainable goals to support Wells’ commitment to environmental stewardship.