What is precast concrete?

Precast concrete components are manufactured off-site in a factory-controlled environment where all aspects of manufacturing can be controlled. These components are then transported to the construction site and installed onto the building or structure.

For several decades, architects and designers have understood and appreciated precast concrete’s benefits as they have built projects in every market segment and in every architectural style. In addition to its structural and durability features, precast concrete panels can be produced in any shape, size, color and/or texture. From the most basic warehouse to award-winning stadiums, museums and historical structures, architectural precast concrete is the construction market’s system of choice.

What is PCI certification?

PCI Certification is acknowledgement by an independent third party that an object, person, or organization has met stated requirements. For PCI’s plant certification program, these requirements include industry, national, and international standards.

Benefits of PCI Certification:

- Reduces risk

- Provides the highest probability of a successful project

- Enables prequalification of bidders

- Helps ensure the finished product meets expectations

- Requires less supervision and field inspection, saving time and money

PCI Architectural Certification Program

The Precast/Prestressed Concrete Institute (PCI) has been administering its certification program for over 50 years and is the most comprehensive, thorough, and specified certification program in the industry. The program is developed, managed, and improved upon with input from over 160 plants in the U.S., Canada, and Mexico, the A/E/C community, and specifiers. This gives architects, designers, and owners the peace of mind to know that precast concrete products manufactured in PCI-certified plants meet the strictest quality standards.

All your architectural expectations met.

PCI’s architectural precast certification program aligns each producer’s capabilities with the specific markets they serve. It establishes superior products, a third-party inspection mandate, and performance requirements for all certification categories. It also includes criteria for producers that have advanced complexity capabilities and sets more accurate aesthetic and tolerance criteria for structural and industrial applications.

PCI precast concrete producers are embracing technology and applying it to the plant-cast concrete delivery system. Classifying PCI precast concrete producers based on their demonstrated capabilities to produce products of varying complexity shows our commitment to improve and collaborate – and that is how precast builds.

Production

Installation

Completion

Creating categories.

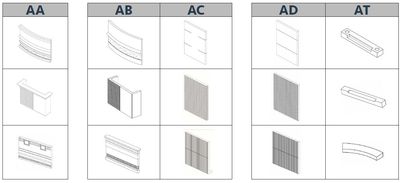

Each PCI-certified architectural precast concrete producer will be certified in one of five categories. All five certification categories (PCI AA certification through PCI AT certification) require high levels of color and finish consistency. These categories define the producer’s manufacturing capabilities based on the type of architectural precast concrete products they typically produce.

Defining precast manufacturing capabilities.

As part of the certification process, each producer must manufacture three mockup panels to demonstrate their ability to meet specific category criteria for color consistency, and finishing and forming capabilities. The required mock-up pieces for each category are shown.

PCI certification benefits.

Certification assures that the precast concrete components are manufactured by a company that adheres to nationally accepted standards, have comprehensive internal quality systems in place, and are audited to ensure compliance. It is imperative that design and construction professionals work with a PCI-certified precast concrete producer that is experienced in the product type best suited for their project (PCI AA certification through PCI AT certification).

PCI certification category project examples.

PCI AA Level Certification

PCI AB Level Certification

PCI AC Level Certification

PCI AD Level Certification

PCI Architectural Certification Program FAQs

Why is PCI changing the Architectural Certification Program?

PCI is changing the Architectural Certification Categories in response to requests from the architectural community. These changes will align the architect’s expectations for the complexity of the project with the capabilities of the architectural precast concrete producers. The former A1 Certification Category and Categories BA and CA have been redefined into four Certification Categories. Architectural precast concrete elements will be governed by Categories AA, AB, AC, and AD, which are differentiated by the panel complexity and the production tolerances required. Projects including only small architectural trim units will continue to be governed by Category AT.

What are the main differences in the Architectural Certification Categories?

The Architectural Certification Categories are differentiated by the complexity of the architectural elements and the allowable dimensional tolerances. A matrix that more clearly defines category distinctions is available at here.

Are 3D/BIM requirements part of the Architectural Certification Program?

Precast concrete producers certified in Categories AA and AB are required to provide 3D/BIM precast concrete submittal drawings when required by specifications.

How do I find the architectural precast concrete producers/bidders for each of the Certification Categories?

To find precast concrete producers certified to service your project, go to PCI.org/archcert and search by Architectural Certification Category and geographic location.

Can you provide photographs that will help me understand the differences in project complexity for the various Architectural Certification Categories?

Photos depicting features of the different Architectural Certification Categories, as well as more complete category descriptions, are available for review here.

Why is it important to specify the correct Architectural Certification Category?

It is important to specify the correct Architectural Certification Category to ensure the finished product meets the owner’s expectations. One of the goals of redefining the Architectural Certification Program is to help the designer, construction team, and precast concrete producer better communicate expectations. Using the new Architectural Certification Categories will clearly define the level of complexity for the project.

If I am unsure, should I just specify AA?

No. Your local PCI-certified producer or PCI regional affiliate is ready and willing to review your project and recommend an appropriate Architectural Certification Category for your project.

What happens if I specify "the wrong" Architectural Certification Category?

Over specifying the category could limit the number of qualified bidders. Underspecifying the category could allow (unqualified) bidders that have not demonstrated the desired capabilities to produce the project.

What changes should I anticipate in the process due to the new Architectural Certification requirements?

Aside from the new requirement to choose the appropriate Architectural Certification Category that best defines the project, there will be no additional changes in the design process. After completion of projects in Categories AA and AB, architects and construction professionals will be asked to complete an Architectural Project Survey.

As a designer, I want to specify Category AD for part of the structure and specify Category AA on another part. Can I do this?

Yes, you can. Please consult with your local PCI-Certified producer or PCI regional affiliate to discuss the best way to communicate your expectations on the drawings and in the specifications.

Will all previous A1 producers be qualified into all the new Architectural Certification Categories?

No. Each architectural precast concrete producer will be recertified into a new Architectural Certification Category that reflects the capabilities demonstrated by the facility.

Do the changes to the Architectural Certification Program have any effect on PCI-certified erector requirements?

PCI-certified erectors will be required for Categories AA, AB, and AC. The use of a PCI-certified erector is encouraged for Category AD.

Does the new Architectural Certification Program increase the time I (or my firm) must spend managing a project?

No. The only change to the design process would be the selection of the appropriate Architectural Certification Category for inclusion in the specifications.

When should specifiers start using the new Architectural Certification Categories in project documents?

Specifiers should incorporate the new Architectural Certification Categories in projects bidding July 1, 2021, or thereafter.

When will PCI publish a list of manufacturers certified for each new Architectural Certification Category?

PCI will publish a complete list of manufacturers certified in the new Architectural Certification Categories on July 1, 2021.

What will happen if I continue to specify A1 Certification for my projects?

After July 1, 2021, the A1, CA, and BA Certification Categories will cease to exist. If former Certification Categories are specified after that date, PCI-certified architectural precast concrete producers will contact the specifier prior to bid date to request a certification clarification. The specifier should then issue a bid package addendum clarifying the specific Architectural Certification Category required.

As an architect, what can I do if the GC/CM takes pricing from a precast concrete producer that is not certified in the Architectural Certification Category I have specified for my project?

In most cases, the building owner (or owner’s representative) has the ultimate responsibility for accepting contractors/subcontractors. If a bidding precast concrete producer is not certified in the Architectural Certification Category the project architect has specified, the architect should request that the owner only consider producers having the appropriate Architectural Certification Category for the project.

PCI Certification Category Requirements

Color & Finish

- More than one colored mixture and texture per panel (must include different texturing method) - AA, AB

- One colored mixture and texture per panel - AA, AB, AC, AD, AT

Embedded Material & Veneer

- Thin brick, tile, stone, terra cotta - AA, AB

- Thin brick - AA, AB, AC, AD

Panel Geometry

- Flat panels - AA, AB, AC, AD, AT

- Flat panels with sequential returns* - AA, AB

- Flat panels with single-pour returns - AA, AB, AC, AT

- 3-D form surface (buildups, liners, projections on face) - AA, AB

- 3-D form surface (reveals and liners only) - AC, AD, AT

- 3-D panels and radius (concave, convex) - AA, AB, AT

Technology

- 3-D/BIM precast concrete submittals** - AA, AB

Key Feature Evaluation During Plant Audit Cycle

- AA, AB, AC, AD, AT

*Two-part returns

**Must demonstrate LOD 350 element modeling minimum

***Customer feedback to be obtained per QSM requirements

Production Tolerances

- MNL 135 AA (modified MNL 117) - AA

- MNL 135 (current MNL 117) - AB, AC, AT

- MNL 135 (current MNL 116) - AD

Plant Audit Frequency

- Two audits per year - AA, AB, AC, AD, AT

Erection Tolerances

- MNL 135 erection tolerances (modified MNL 117) - AA

- MNL 135 erection tolerances (current MNL 117) - AB, AT

- MNL 135 erection tolerances (current MNL 117 with modifications for maximum jog) - AC

- MNL 135 erection tolerances (current MNL 116) - AD

PCI-Certified Erector

- Required as of 07/01/2021 - AA, AB, AC

Post-Occupancy Evaluation

- Surveys for all AA projects with one mandatory site evaluation*** - AA

- Surveys for all AB projects with site evaluations as required - AA, AB

Looking for more PCI certification information?

Other available resources:

Architectural Certification Webpage

FAQs

Designer's Notebooks

About PCI Certification

PCI Website

The Precast/Prestressed Concrete Institute (PCI) is a technical institute for the precast concrete structures and systems industry. PCI develops, maintains, and disseminates the Body of Knowledge for the design, fabrication, and construction of precast concrete structures and systems.

PCI Architectural Certification Program Supplemental Requirements

PCI MNL 116 - QC manual for structural precast concrete products

PCI MNL 135 - Manual for tolerances for precast and prestressed concrete construction

PCI MNL 117 - QC manual for architectural precast concrete products